Intergranular Corrosion

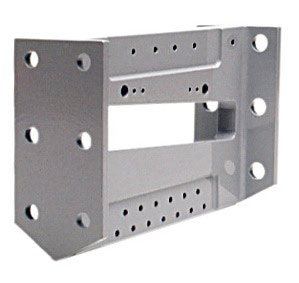

Cessna gear brackets and inboard angles are manufactured using an extrusion process which is geared for high volume, lower cost production. As the aluminum is extruded the molecular structure of the material is altered which makes it more susceptible to developing inter-granular corrosion. Shown here is a top view of an outboard gear bracket with severe inter-granular corrosion. Note how the material expands and flakes off in layers. This is due to the re-alignment of the molecular structure that occurs during the extrusion process. Parts milled from cold rolled aluminum block do not develop this type of destructive corrosion.

Often times this load is enough to simply strip the nut off the end of the bolt which frees the gear leg and allows it to fold under the aircraft. If the wheel or gear leg hits something like a large rock, a log, a chuck hole, etc. the gear leg can easily exert enough shearing force to simply cut or tear the main landing gear attach bolt in half.

Often times this load is enough to simply strip the nut off the end of the bolt which frees the gear leg and allows it to fold under the aircraft. If the wheel or gear leg hits something like a large rock, a log, a chuck hole, etc. the gear leg can easily exert enough shearing force to simply cut or tear the main landing gear attach bolt in half.